集成电路中激光打标机也在神出鬼没

集成电路是一种微型电子器件或部件,通过了一定的特殊工艺,将电路中所需要的晶体管、电阻、电容、和电感等电子元器件利用布线互连在一起,制作在一小块或几小块导体晶片或介质基片上,然后将它们封装在一个管壳内,这样就成为了具有特定需要电路功能的微型结构。这就使得所有的电子元器件连接成为了一个整体,我们只需要按照特定的需求进行设计和集成,就可以实现一定的特定功能,这样就使得现在的电子元件不断朝着小型化、低功耗、智能化、高可靠性等方面不断迈进。在我们的实际生活中集成电路就在现在的电视机、手机、电脑、相机等的众多领域应用非常广泛,同时还在现在的军事、通讯、遥控等方面也应用非常广,可以说集成电路的发展,给予了我们现在科技无穷的魅力。然而在集成电路快速发展的过程中,由于内部构件的日益复杂以及体积空间的不断搜小,使得现在的集成电路加工,不得不寻求更加精密以及性能稳定的加工来进行加工生产。

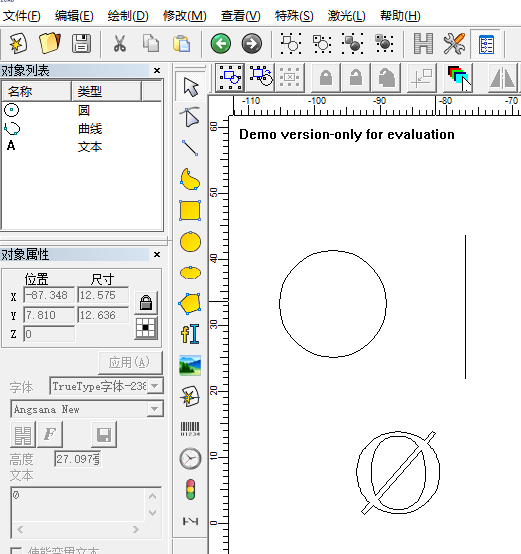

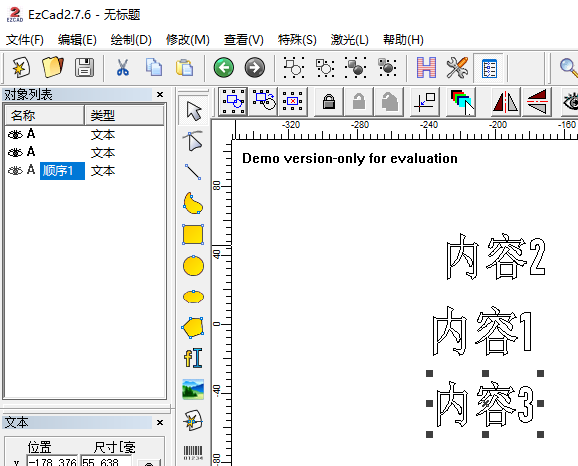

特别是在现在集成电路的标记过程中,由于不同的集成电路所运用的行业和功能有所不同,基本上都是按着特定的实际需要来进行设计的,这就使得不同的集成电路必须有可用于区分的标记信息。而利用传统的信息标记方式,由于集成电路的集成化水平高、体积小,内部构件复杂,很容易造成集成电路的损坏和标记效果的不理想,有的甚至难以标记。但是利用现在的光纤激光打标机进行标记,可以容易的解决这一问题。由于光纤激光标记是利用高能量密度的激光对集成电路表面进行局部照射,使表层材料汽化或发生颜色变化的化学反应,从而留下永久性标记的一种打标方法。目前光纤激光打标可以打出各种文字、符号和图案等,字符大小可以从毫米到微米量级,这对于现在的集成电路的加工有着重要的意义,能够极大的给予现在集成电路更加广阔的发挥空间。同时激光加工效果精细有质感、不容易磨损、能够长期辨识,因此现在众多的集成电路制造商首选采用现在的激光标记进行加工,不仅可以满足现在集成电路的批量化、规模化生产,同时还可以按着具体的实际需要进行个性化的加工。

本文链接:https://www.goldlaser.cn/news/664.html 转载需授权!